| The Company adheres to strict quality standard-IATF : 16949-2016 & ISO-9001-2015 | |

| It will follows two prong approach to maintain high quality standard –(i) inspection and (ii) testing. |

| Will conducts online inspection by dial and comparator gauges. | |

| Will carry out –100 % -Magnetic Particle Inspection (MPI-Magnaflux) facility for crack detection. | |

| It has 100% -ECT facility for material and grade sorting for all lot. |

| Metallurgical Testing Laboratory comprising off : | |

| SpectroMachine-portable. –( Out source-TUV –SUD) | |

| Hardness Tester-Make-SAROJ & FIE | |

| Polishing Machine.-Make-ABC | |

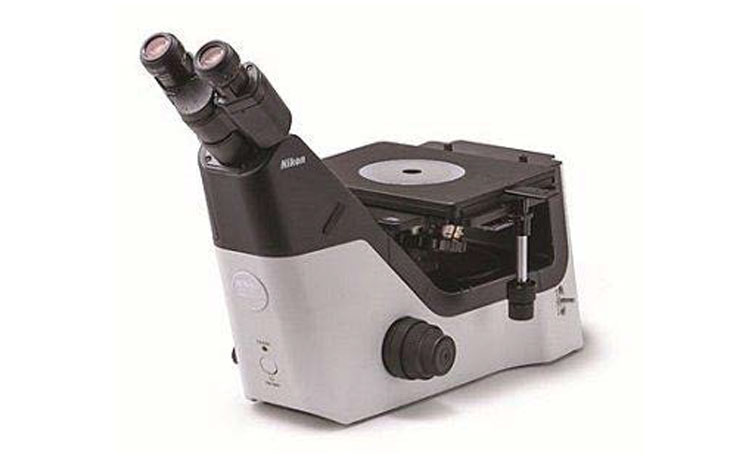

| Microscope-Make-Nikon | |

| Metrology Testing Laboratory comprising off. | |

| Roughness Tester with Gauge | |

| Linear Height Gauge | |

| Co-Ordinate Measuring Machine-Make-Accurate | |

| Contracer Measurement Machine-Make-ZAISS | |

| Comparator Gauges -MarutiInstruments. | |

| Contour Machine-Make-ZEISS ( GMBH) Contour Measuring System Model-Contourecord1600 G | |

| Model-“Spectra” 3D Coordinate Measuring MachineMeasuring range of 500mm x 600mm x 400mm in CNC mode. |

| Contour Machine-Make-ZEISS ( GMBH) | |

| Auto Element Judgment ( AI Function ) | |

| The 1600G automatically determines thetype of element ( point, line, circle). |

| Metallurgical Microscope | |

| Make Nikon | |

| Model Eclipse MA100N |